Butcher Blocks

Butcher Blocks: Safety, Hygiene, and Regulations

A butcher block is a central element in any cutting workshop, artisanal butcheries, or industrial meat processing facilities. It serves as the surface on which meat is cut, prepared, or butchered. Choosing and using a butcher block involves more than just durability—it must meet strict hygiene, safety, and durability standards.

Essential Features of a Good Butcher Block

-

Suitable Material

-

Professional butcher blocks are typically made from hardwoods (beech, maple, or iroko) or food-safe synthetic materials (high-density polyethylene, polypropylene).

-

Wood offers good resistance to knife impacts and a surface that doesn’t dull blades quickly.

-

Synthetic materials are easier to clean and limit the absorption of liquids and bacteria.

-

-

Hygiene and Cleaning

-

Blocks must be regularly cleaned and disinfected according to HACCP standards to prevent cross-contamination.

-

Wooden blocks should be brushed and washed with hot water, then properly dried. Synthetic blocks can be washed with high-pressure jets or in industrial dishwashers.

-

-

Robustness and Stability

-

A butcher block should withstand repeated knife and bone saw impacts.

-

The legs or supports should ensure perfect stability to prevent slipping and accidents.

-

Current Regulations

The use of butcher blocks is regulated by various European and national standards and directives:

-

European food safety standards: Directive 2006/42/EC (Machinery Directive) for equipment related to cutting.

-

Food hygiene: Regulation EC 852/2004 on food hygiene, requiring surfaces to be easy to clean and resistant to contamination.

-

Local safety regulations: Some municipalities or veterinary services impose periodic inspections to ensure the hygienic condition of butcher blocks.

User Safety

-

Butcher blocks should have anti-slip features or stable legs to prevent accidents while cutting.

-

The edges should be rounded to reduce the risk of injury and facilitate cleaning.

-

It is also advisable to use surface markings or signage to designate different work areas for various types of meat (beef, pork, poultry) to avoid cross-contamination.

Maintenance Tips

-

Regularly oiling wooden blocks with food-grade mineral oil helps extend their lifespan and prevent cracks.

-

Inspect blocks for deep cracks or splinters that could harbor bacteria and foreign objects.

-

Replace a damaged or worn-out block to ensure safety and hygiene.

Conclusion

The butcher block is not just a cutting surface; it is a professional tool subject to strict regulations. Choosing a quality block tailored to the needs of the workshop ensures employee safety, food hygiene, and material durability. In an environment where sanitary controls are frequent, complying with regulations and properly maintaining the blocks is essential for any meat professional.

16 other products in the same category:

-

-

METRO PROFESSIONAL GMW1125 Professional Microwave Oven

€444.00 -40% Off €266.40 Tax incl. - €222.00 Tax excl. -

Stainless steel hand wash station with femoral and knee operation – Optimal...

€144.00 Tax incl. - €120.00 Tax excl. -

-

ChatGPT a dit : VELTIA V7 TRIBLADE Hand Dryer – Matte Grey

€694.80 -45% Off €382.14 Tax incl. - €318.45 Tax excl. -

-

Tournus stainless steel shelves 400 x 1200 mm – Réf : 509 752

€204.12 -50% Off €102.06 Tax incl. - €85.05 Tax excl. -

-

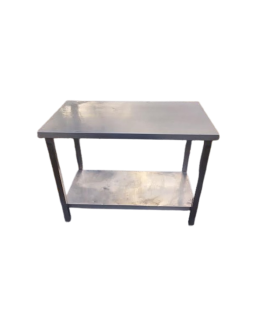

copy of Stainless steel table with shelf – D 1000 mm – L 700 mm

€156.00 Tax incl. - €130.00 Tax excl. -

-

-

-

-

-

-